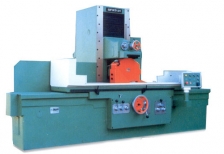

SGM 500

Grinding machine SGM 500 can be manufactured with a class of accuracy B and A according to the standards GOST 273-90 (ISO 1986-85), GOST 13135-90 (ISO 1985-85, ISO 1986-85, ISO 4703-84)

Technical specification of SGM 500

| Technical data | Dim. | Value |

|---|---|---|

| Work table | mm | 500x1500 |

| Electromagnetic plate size | mm | 500x1500 |

| Maximal workpiece size | mm | 1500x500x400 |

| Grinding wheel | mm | 450x63x203 |

| Maximal peripheral velocity | m/sec | 35 |

| Grinding spindle turning speed | m/min. | 1500 |

| Automatic vertical travel range | mm | 0,005-0,1 |

| Automatic range of transverse displacement | mm | 0,5-30 |

| Minimal hand-operated vertical travel | mm | 0,005 |

| Rapid traverse speed vertical travel | m/min. | 0,4 |

| Rapid traverse speed cross travel | m/min. | 3 |

| Motor power | kW | 11 |

| Weight | kg | 8600 |

Standard equipment

Electromagnetic table with fixing elements, Stand for static balancing of the grinding wheel, Flange for setting the grinding wheel, grinding wheel removal tool, Mandrel for balancing the grinding wheel, Sharpening tool for the grinding wheel, Lubricating-cooling system for the cutting area, Lighting of lathe's work area, Set of spare fast-wearing parts and elements for 5000 hours, Set of service wrenches, Wooden pallet with polyethylene cover packaging